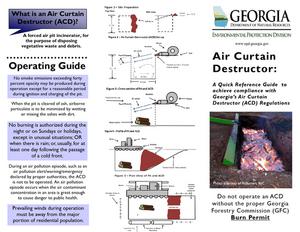

What is an Air Curtain Destructor (ACD)?

A forced air pit incinerator, for the purpose of disposing

vegetative waste and debris.

Operating Guide

No smoke emissions exceeding forty percent opacity may be produced during operation except for a reasonable period

during ignition and charging of the pit.

When the pit is cleared of ash, airborne particulate is to be minimized by wetting

or mixing the ashes with dirt.

No burning is authorized during the night or on Sundays or holidays, except in unusual situations; OR

when there is rain; or, usually, for at least one day following the passage

of a cold front.

During an air pollution episode, such as an air pollution alert/warning/emergency

declared by proper authorities, the ACD is not to be operated. An air pollution

episode occurs when the air contaminant concentration in an area is great enough

to cause danger to public health.

Prevailing winds during operation must be away from the major

portion of residential population.

www.epd.georgia.gov

Air Curtain Destructor:

A Quick Reference Guide to achieve compliance with Georgia's Air Curtain Destructor (ACD) Regulations

Photo courtesy of AirBurners, INC.

Do not operate an ACD without the proper Georgia Forestry Commission (GFC)

Burn Permit

Always obtain a Burn Permit

Call the GFC County Unit or Apply online:

www.gfc.state.ga.us/online-permits

(enter your county, `ACD', and phone number; then submit required

information)

At all times, adhere to all local ordinances and regulations regarding

use of an air curtain destructor.

No more than one ACD can be operated within a ten acre area at

one time.

A damaged ACD with an air duct or manifold that cannot pass an even flow of air across the top of the pit is not authorized.

The ACD must be operated to prevent air, land or water pollution, safety/health

hazards, or nuisances.

The amount of dirt/soil on or in the material being burned must

be minimized.

Operating Procedures

1) Site Location and Preparation

-Select a site which will likely have a low water table, can be easily excavated and is no less than 300 feet from occupied structures.

2) Pit Preparation

-Excavate the pit using either a front-end loader or backhoe. The pit dimensions are 8 feet wide x 12-15 feet deep x 15-30 feet long (pit length depends on length of ACD manifold). In no case should the 8 feet width be exceeded.

-The pit must be excavated with at least three vertical sides in soil capable of maintaining vertical walls of 15 feet depth with out failure. Additional wall support may be necessary. Caution must be exercised to insure that walls are not undercut during excavations.

-If a front-end loader is used for the excavation, the end used for travel must be filled in with dirt beginning at the end of the manifold and filling up the ramp. (See Figure 4)

3) ACD Manifold Set up

-Using a small berm of soil (1 to 1/2 feet high) place the manifold (plenum and nozzles) such that the manifold is properly supported and the space between the manifold and ground is sealed. Rotate the manifold until the air curtain will be directed at an imaginary horizontal line 24 to 36 inches below the top of the opposite wall. Slide the skid containing the blower and motor into place and connect to manifold. (See Figure 2)

4) Ignition Procedures

-Get a Burn Permit from the GFC

-Load the pit half full with the homogeneous mixture of trees, logs and large brush. Douse the wood with 1/2 gallon of fuel oil putting the majority of the fuel oil on the wood at the front center side of the pit. Ignite the wood at the same point. Allow sufficient time for the fire to take hold before introducing any air from the ACD. As the fire grows in intensity, gradually bring the blower up to the optimum speed (generally between 1,100 and 1,400 RPM, depending on the size, type and make of the blower).

Do not use tires or highly volatile solvents such as mineral spirits, gasoline, etc. for ignition.

Operating Procedures

(continued)

5) Loading Procedure

-Once the fire reaches full intensity, successive intermittent charging may begin.

-The intervals between charges may be determined by observing the burning rate. Generally, if the fire is kept at its maximum intensity, it will keep one man, operating a front-end loader or clamshell bucket constantly busy. The charges should be alternated between light and heavy material. The material should be charged toward the rear of the pit under the ACD manifold.

-The pit should not be overloaded; that is the material should not be piled up so high that it will protrude above the air curtain. Also, no materials should extend outside the boundaries of the pit and air curtain where sufficient air is not available from the nozzles.

6) Maintenance and Safety Requirements

-Ash removal is required in order to maintain efficient and proper combustion. Ashes should not be allowed to build up in the pit to higher than 1/3 the pit depth or to the point where they begin to impede combustion and are blown out of the pit, whichever occurs first.

-If spalling, "cave off" occurs during operation, a new pit must be constructed and the existing pit filled with soil.

-Any accumulation of water in the pit must be removed prior to operation.

-For reasons of public safety, a fence or barrier surrounding the combustion pit is recommended.

-A "stop guide" or restraint must be provided at the loading side of the pit in order to keep the loader from getting too close to the pit during the charging operation.

Only wood wastes consisting of trees, logs, large brush and stumps relatively free of soil may be burned. Leaves, sawdust, other densely packed wood wastes, paper (any type), chemically treated, coated or impregnated wood CANNOT be burned.